FAQs

Listed here are some of the more frequent questions we get asked with regards to commissioning, servicing, maintenance, installation and repair services we provide.

If your questions is not answered here feel free to get in touch.

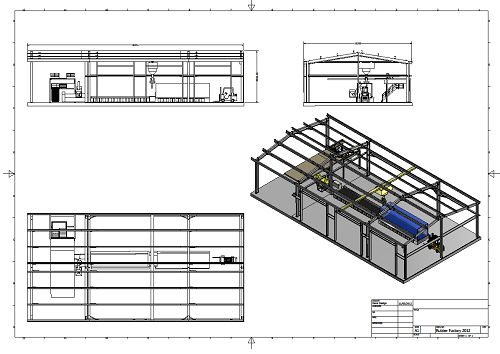

- What are the dimensions of a line?

- A new production line, each consisting of a fully Automated Dosing & Mixing System, which will be built within the line.

Dimension 32m long X 2m wide X 4.5m height and a capacity of the new production line 500 – 550 per hour.

- A new production line, each consisting of a fully Automated Dosing & Mixing System, which will be built within the line.

- What products can we make?

- Almost any product that can be extruded, however, the materials suit wood replacement products.

- Does the company provide financing?

- No we do not provide financing but in some cases Dena will take shares in the project and reduce the price of the line.

- Are the products certified?

- Certification is down to the producer to organise however there have been tests carried out by qualified bodies ( Bradford University ) that shows the attributes of the materials.

- How much material can be extruded per line?

- Approximately 500 kg per hour.

- What is the lead time from order to supply of the lines?

- Approx. 6-7 months to delivery.

- What is the length of time from the point of being delivered at factory to being operational?

- Providing all services are ready to be connected approximately two weeks.